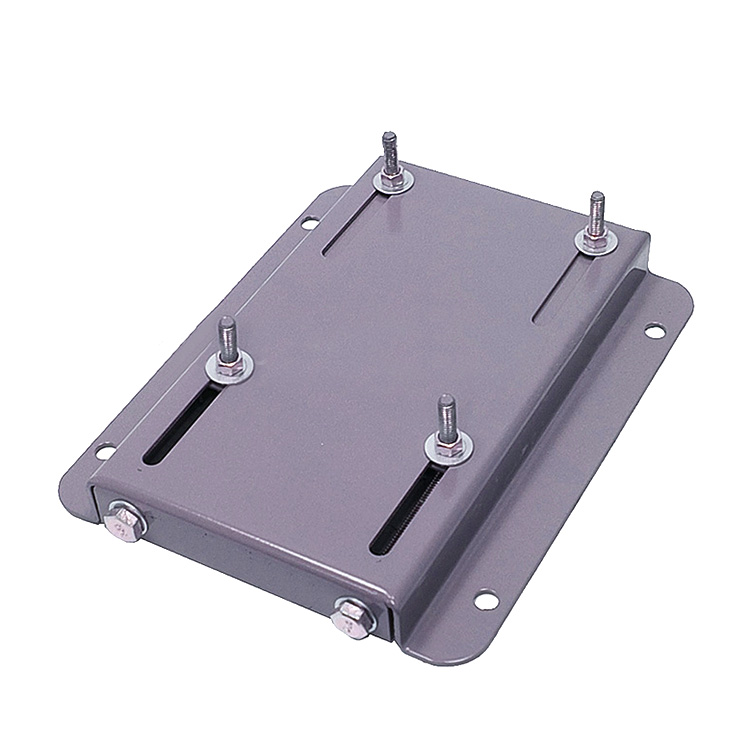

motor base

As one of leading motor base manufacturers, suppliers and exporters of mechanical products, We offer motor base and many other products.

High Quality, Ethically Sourced Materials

electric motor adjustable base

adjustable motor base manufacturers

motor base blocked

Mail:[email protected]

Manufacturer supplier exporter of motor base

When it comes to electrical motors, some of the popular choices are three phase motors, high voltage motors and single phase motors. They each have their own unique use, which is why it’s often a good idea to know the difference between them. Three phase electrical motors have certain characteristics and they are used often, even in our homes. They mainly consist of two circuits, called the AC and DC circuit.

These three phase motors use both AC and DC currents to function although it seems like only one phase is used – it is in fact three phases, two DC circuits and one AC circuit to be precise. The first phase supplies the electric poles and the second and third phases are those that carry the current to other electrical circuits. The size and flow of electricity works differently in these motors than in other motors, which is why these motors are ideal for specific applications, especially when a higher output is needed like industrial environments and processes, for example.

Reducer Gearbox High Torque

Single phase electric motors are known for their quality as they have been designed to suit various environments, especially where a high torque capacity is needed. Standard features of these motors include heavy duty ball bearings, single phase poles, manual overload protection, a start capacitor, high torque output and a specially designed shaft for better performance. These motors are designed with longevity in mind, and they are very versatile, meaning they can be used for many different applications.

single phase electric gear motor

High voltage electrical motors have a core with different coils. As the current in the main coil is transformed, a core with a magnetized space is created which is then carried through to the secondary coils. The two important stages used in these products are single phase and the three phase, which is divided into AC or DC current.

Please contact us for details.

We warmly welcome customers both at home and abroad to contact us to negotiate business, exchange information and cooperate with us.

Motor Base , Motor Slide Adjustable Motor Slide Base

These air motors can be coupled with gearboxes to increase torque and reduce speed.

Gast pneumatic motors with the same vertical base series are sold

It does not build up heat or sparks make air motors ideal for use in flammable or explosive applications.

linear lifting actuator motorized base lift linear motor actuator

Less than 55dB Powder coating 2 minutes continues use followed by 18 minutes not in use