Description

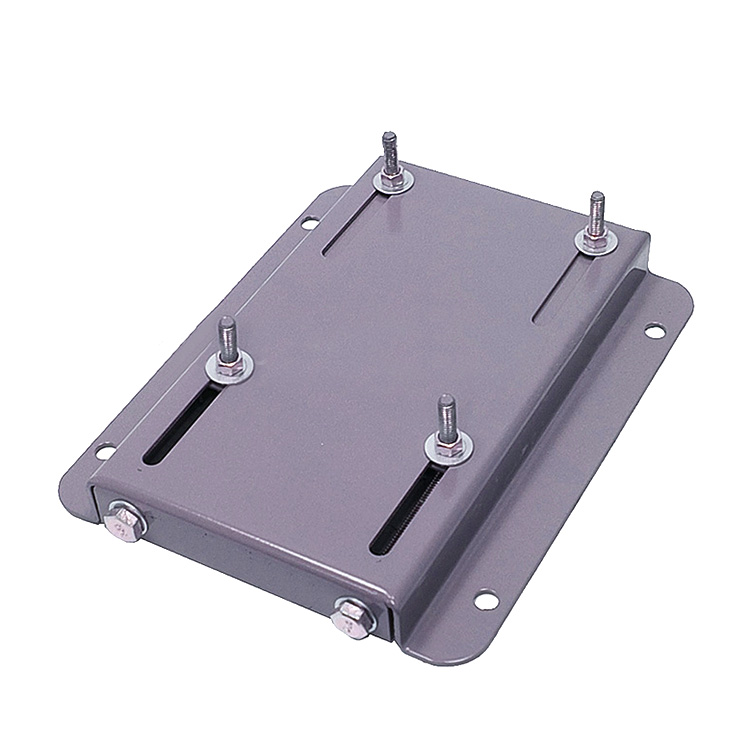

Material:

1)gray iron, ductile iron, malleable iron, steel, aluminum

2)Weight range from 0.1kg to 100kg

3)Auto-molding line, squeeze machine, hand molding for option

4)Resin sand, hot sand, green sand molding for option

5)Melting facility: 500kg/1T medium frequency electric furnace; 3T/5T/7T cupola

6)Surface finish: paint, E-coat, epoxy powder coating, zinc plating…

7)Packing:as per customer’s requirements

Our advantage:

1)We have our own factory ,so the price will be competitive.

2) Process: Resin/Soluble sand casting, Investment casting (Lost wax/Soluble glass).

3) Applied software for specification drawings: Pro/E, AutoCAD, Solidworks, etc.

4) Precision machining: CNC, NC lathes, boring machines, milling machines, bench drilling machines, etc.

5) Surface Protection: oiled (rust-proof), electroplating, hot dip galvanizing, nickel or chrome plating, painting, powder coating.

Product Design and casting simulation

Successful parts are original from successful design. We own high level engineers on the product design .They are good at make drawing using the software of CAD.PROE,SOLIDWORKS for assuring production process well.

Our technical group have rich experience in casting process, so we can put forward reasonable suggestions to the product structure design on various performance, process parameters to solve the customer’s requirement, set up the 3D model, get the results from pouring simulation analysis. Then modify and optimize the scheme to determine the correct casting process.

Our Inspection Equipment:

Direct-reading spectrograph,metallographic microscope,hardness tester,brinell hardness tester,thermometric indicator,universal testing machine,carbon and silicon analysis meter,magnetic powder flaw detector,digital ultrasonic flaw detector etc.

Our Service:

1.Your inquiry related to our products or prices will be replied in 12 hours.

2.Individual formula according to customers’ special drawing requests.

3.Manufacturer with large capacity,ensures the fast production cycle after

confirming the order.

4.Protection of sales area and private information for all of our customers.

Quality Control:

We have a full set of quality control system to guarantee best product quality. Depending on the products, we can make different Item Testing Plan, Manufacturing procedure etc.

Raw material control

Chemistry spectrum analysis

Mechanical property

Metallographic analysis

Ultrasonic testing

Magnetic testing

Radiographic testing

Dimension inspection

Visual inspection

Penetrant testing

Leak testing

Hardness test

Micro-structure tester after heat treatment

Machining Ability

Our machining shop located in Qingdao using the latest CNC equipment to provide our customer with high quality products.

Horizontal and Vertical Machining Center

CNC lathe and normal lathe

CNC drilling and milling Center

Other assistant equipment